news

09.07.2024

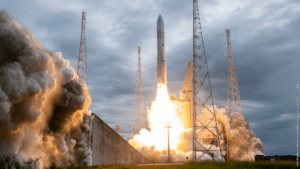

Ariane 6 inaugural launch – mission successful

Ariane 6 is a high-capability launcher designed to ensure Europe’s independent access to space. Ariane 6 was developed by ArianeGroup under a European Space Agency (ESA) programme and provides an efficient answer to the growing needs and diversified missions of Arianespace’s institutional and commercial customers.

It is powerful, highly versatile, modular, and draws on the experience of Ariane 5 to guarantee reliability and precision. Its optimised industrialisation process is designed to allow high production rates and offer customers optimum efficiency. The procurement chain managed by ArianeGroup involves more than 600 companies of all sizes in 13 European countries – a great cooperative venture, in both human and industrial terms.

Scroll down to find out about the launcher

Space technologies and infrastructures play an increasingly important role in everyday life.

Ariane 6 was designed to offer the same level of precision and reliability as Ariane 5, with unparalleled performance and versatility.

ESA’s Ariane 6 programme is in every respect “made in Europe”. ArianeGroup is lead contractor and design authority for the launcher system.

ArianeGroup manages the entire procurement chain for the Ariane 6 launcher and has set up a state-of-the-art industrial process designed for zero defect production with shorter cycle times.

Ariane 6 is the epitome of a cooperative project, the shared passion of thousands of people across Europe.

02

Interacting with the launcher

Ariane 6 is a versatile launcher capable of carrying out a wide range of missions, for a great variety of payloads to all types of orbits, thanks to its two versions, Ariane 62 with two boosters and Ariane 64 with four boosters.

Ariane 62

2 ESR – Equipped Solid Rocket (Boosters)

Ariane 64

4 ESR – Equipped Solid Rocket (Boosters)

Height

56 m (short fairing)

56 m (short fairing) 62 m (long fairing)

Total lift-off weight (depending on weight of fuel and payload)

530 to 540 tonnes

850 to 870 tonnes

Lift-off thrust

8,400 kN (about 857 tonnes)

15,400 kN (about 1,570 tonnes)

Geostationary transfer orbit (GTO)

4.5 tonnes

11,5 tonnes

Sun synchronous orbit (SSO)

7,2 tonnes

15,5 tonnes

Low Earth orbit (LEO)

10,3 tonnes

21,6 tonnes

Earth escape orbit

2,6 tonnes

6,9 tonnes

Lunar Transfer Orbit (LTO)

3,5 tonnes

8,6 tonnes

Ariane 6 industrial process at Europe’s Spaceport

See the video

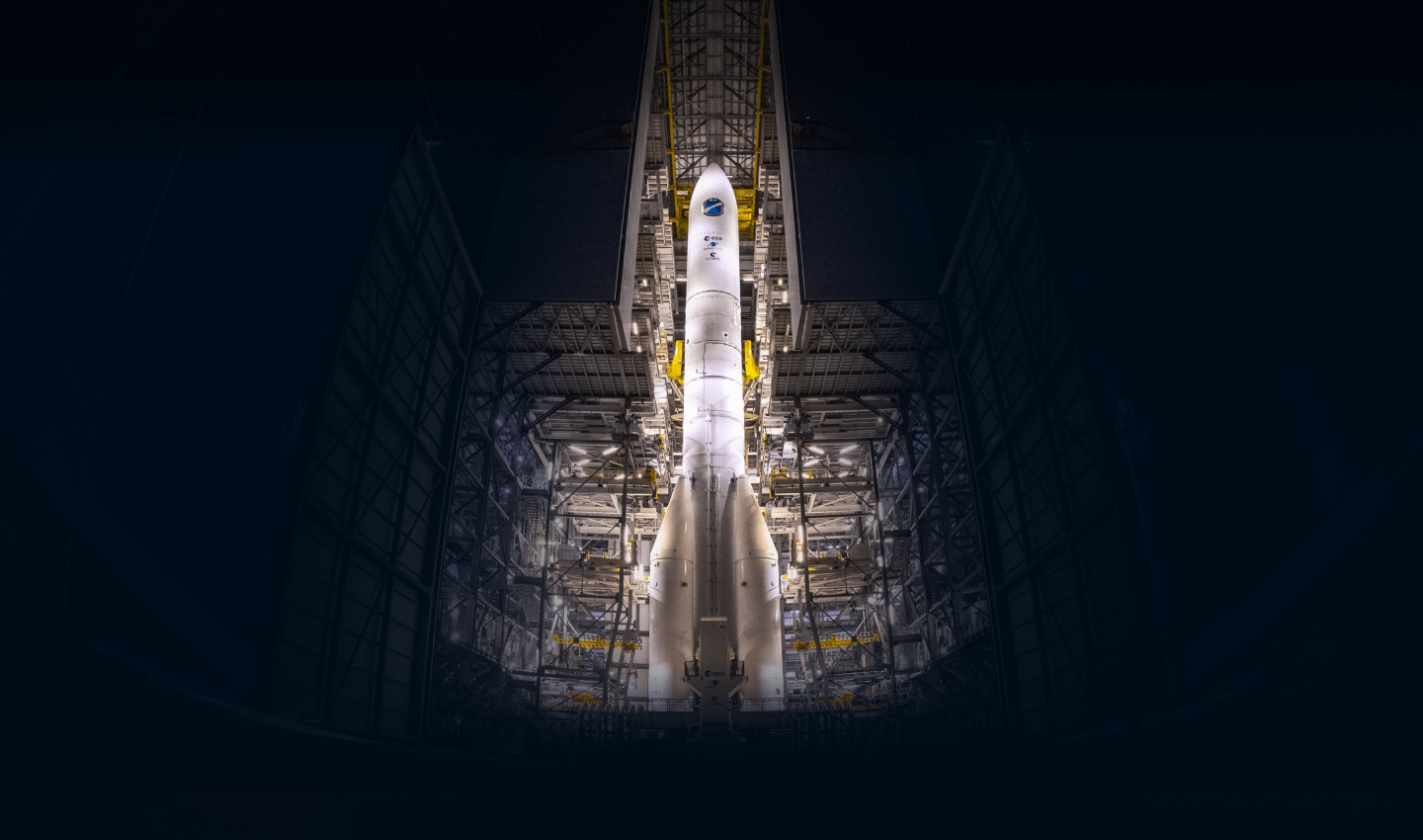

The launch campaigns involve the Ariane 6 launchers being assembled and readied for flight on the Ariane Launch Complex no. 4 (ELA4) at Europe’s Spaceport in Kourou, French Guiana.

Work is carried out in several areas concurrently, for the production and manufacture of propellants, booster assembly, central core assembly and upper composite preparation respectively.

The main stage, the upper stage and the other components arrive from mainland Europe on the Canopée cargo ship. The stages are assembled by ArianeGroup to form the launcher’s central core in the launcher assembly building (BAL) before being transferred to and installed on the launch pad.

The components of the solid rocket motors delivered by ArianeGroup and Avio are assembled at Europe’s Spaceport by Europropulsion and the engines are filled with propellant by Regulus. They are then delivered to ArianeGroup, which assembles and prepares the boosters in the Booster Finishing Facility. They then go to the Booster Storage Building before being installed on the launch pad, on either side of the central core.

The upper composite and the payloads are prepared by Arianespace together with its customers. This specific process begins with preparation of the payloads in specialised premises. The upper composite is then put together in the encapsulation building, with the payloads and the two half-fairings. This assembly then goes to the launch pad where it is installed on the launcher using the mobile gantry.

Find out more about Arianespace services

See more